KingRCT3 a dit:C'est vrai que plus souvent on a ces petits carrés noirs de caoutchouc :

Ce sont des "Silentbloc", c'est très utilisé dans l'automobile

KingRCT3 a dit:C'est vrai que plus souvent on a ces petits carrés noirs de caoutchouc :

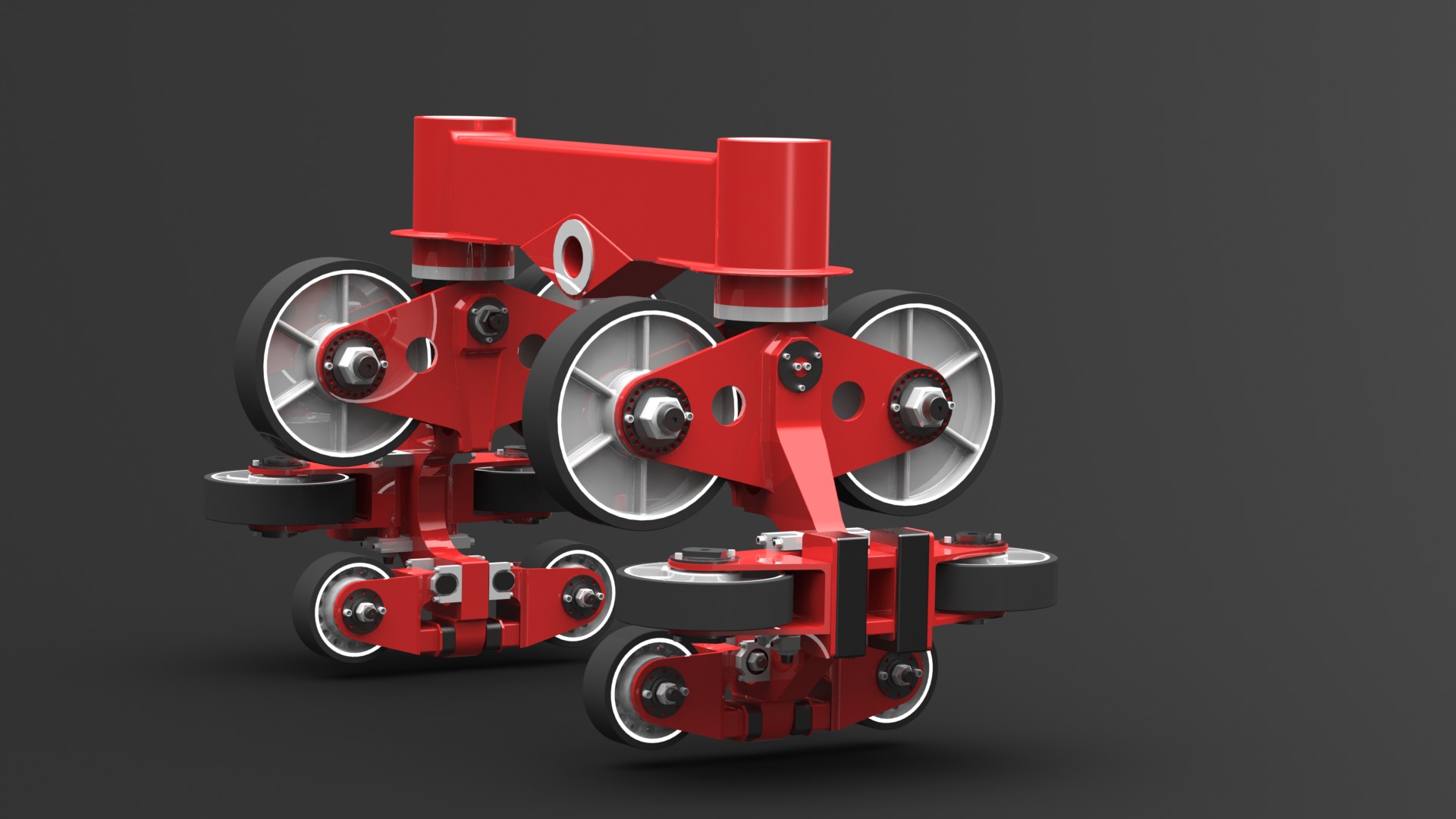

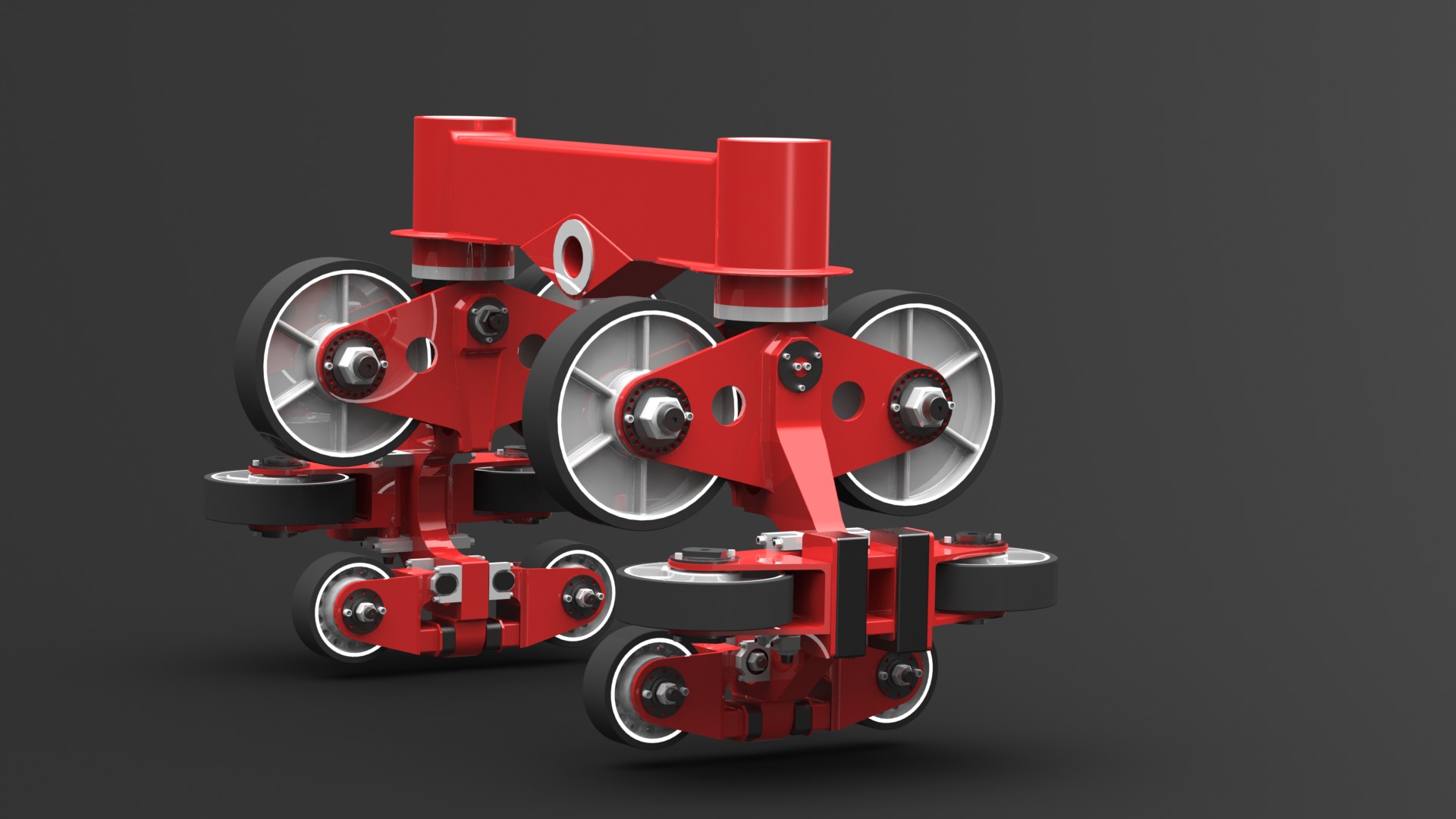

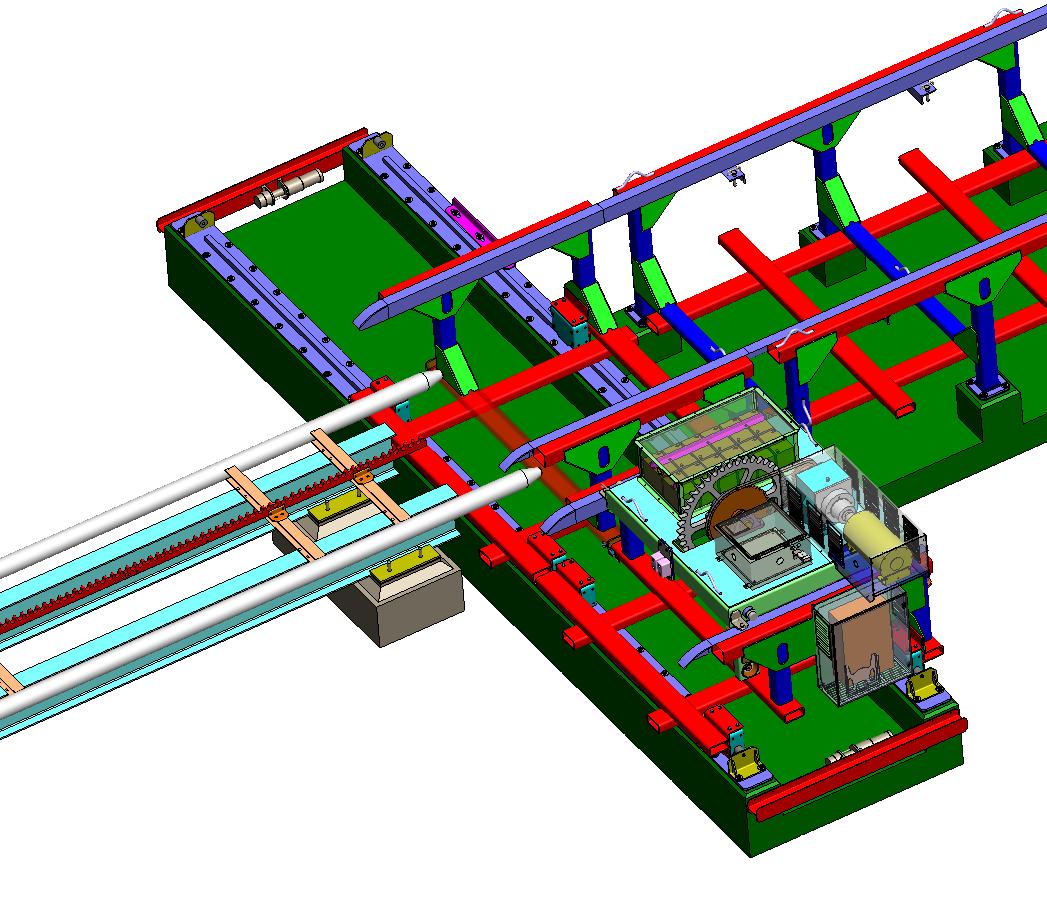

Quelles sont les dimensions? Le nombre d'unités disques, leurs dimensions et la puissance des moteurs sont calculées pour chaque installation. Pour donner un example, une voiture pesant 2000 kg peut être lancée à une vitesse de 20 m/s avec une accélération de 1,6g par une série de 45 disques; chaque unité disque inclût un volant pesant 100 kg, un disque de 400 mm de diamètre et un moteur èlectrique standard d'une puissance variant entre 1,1 et 2,2 kW tournant entre 1500 et 3000 rpm (seulement la puissance et la vitesse des moteurs varient d'un disque à l'autre); la consommation totale sera de l'ordre de 60 kW pour lancer une voiture toutes le 30 secondes. Il est évident que, pour des applications moins performantes, les nombre et les dimensions des unités disques seront proportionnellement réduites.

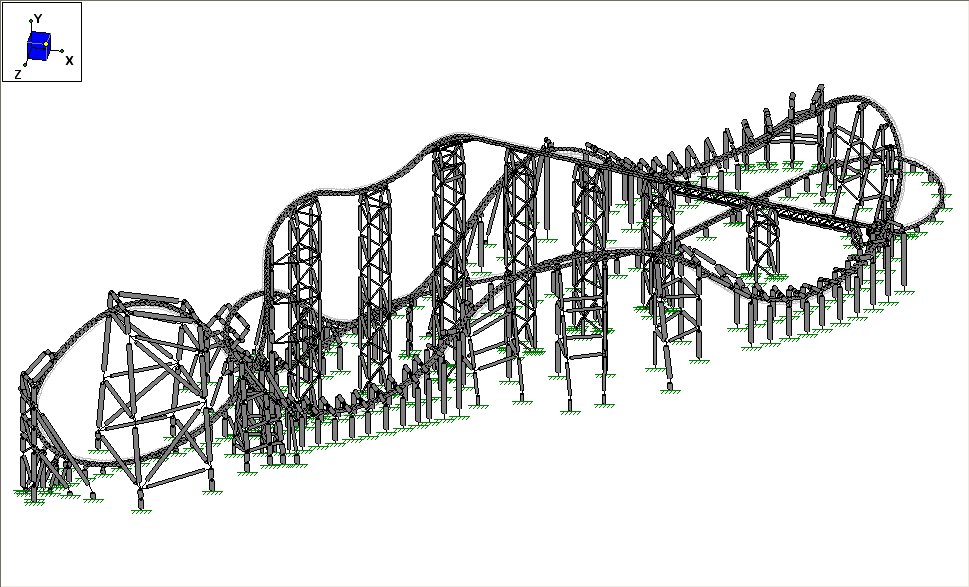

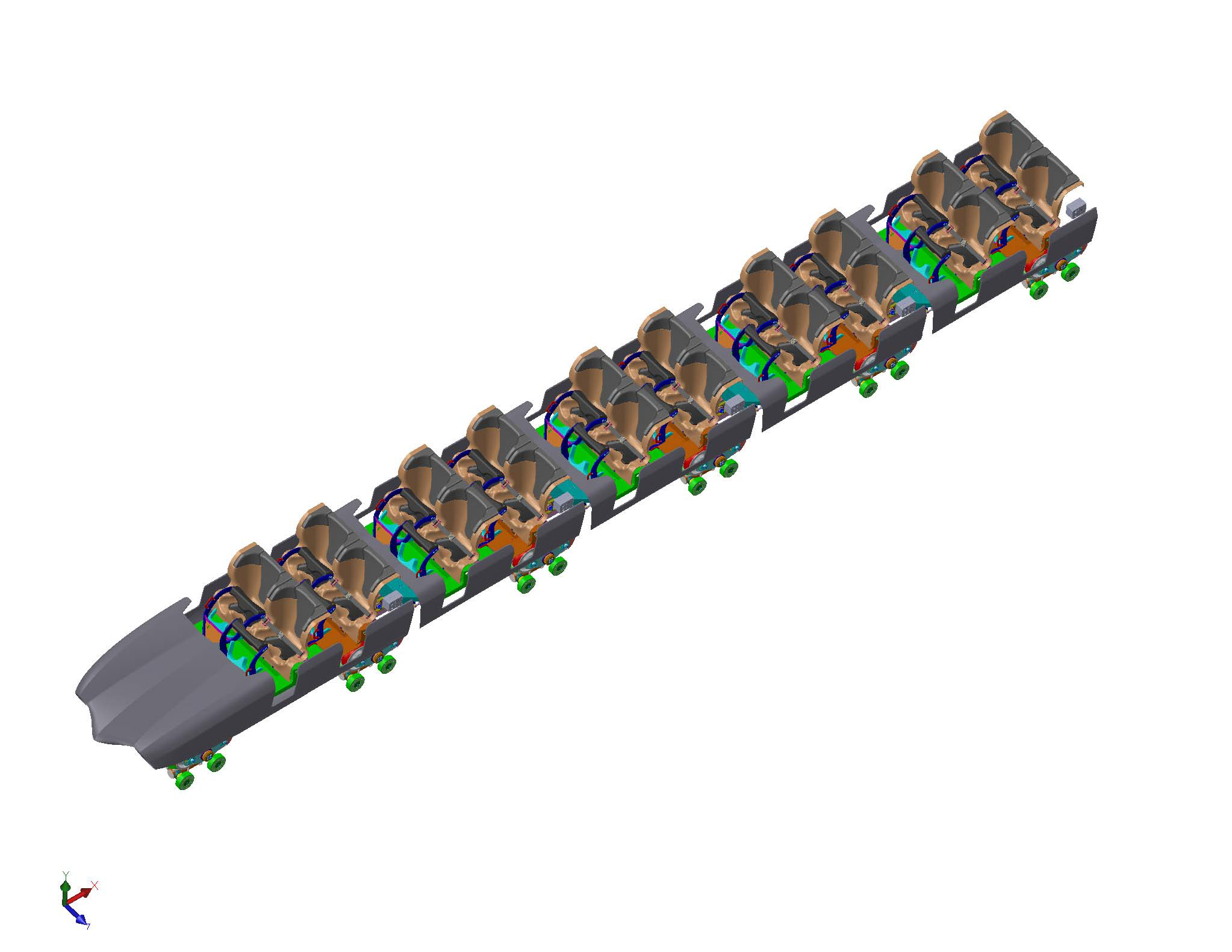

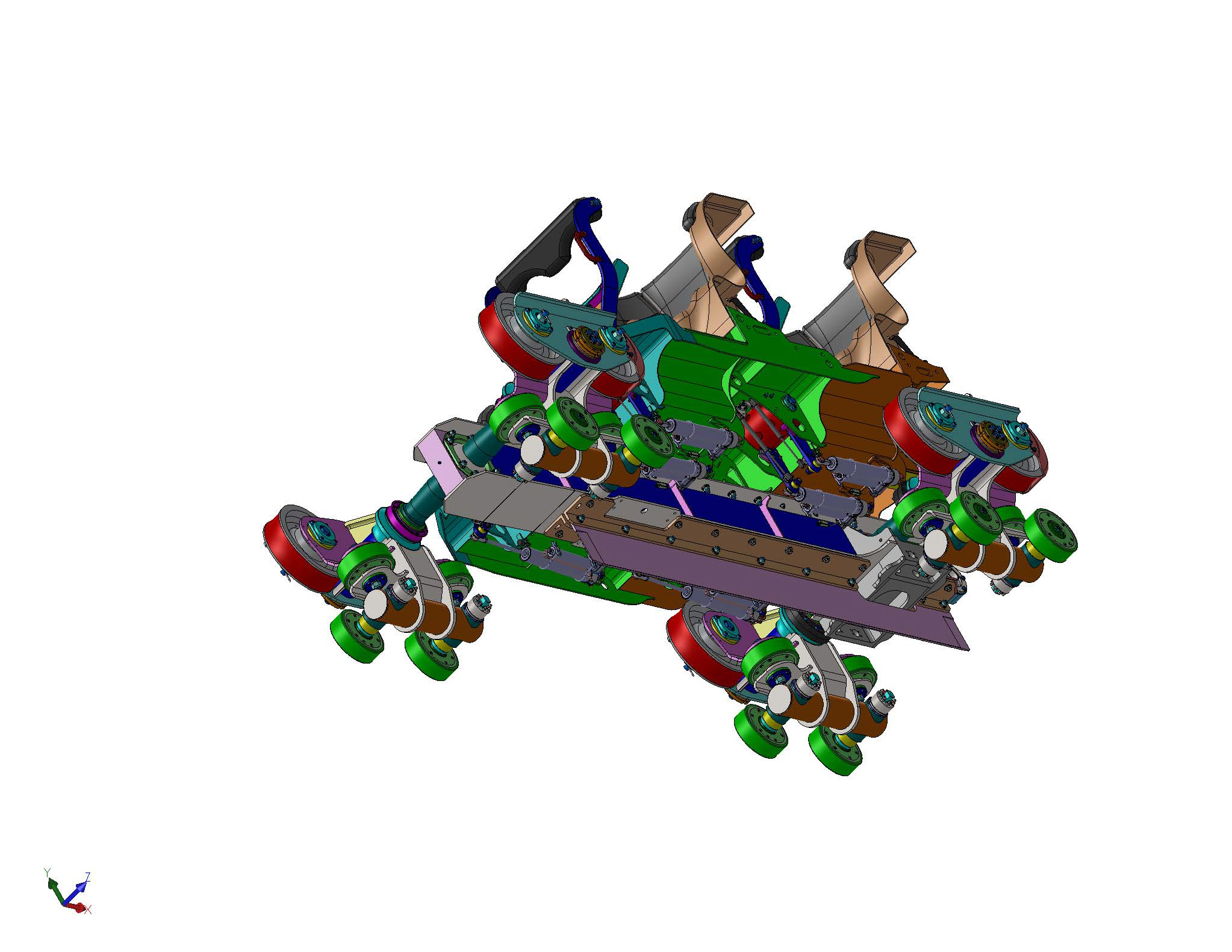

“Our products are so complex that it would be impossible to develop them without an exceptionally efficient 3D design and simulation solution,” says Fabbri. For Fabbri Group, that solution is Solid Edge® software. Solid Edge offers full interactivity among the various design environments (such as assembly, part and draft).

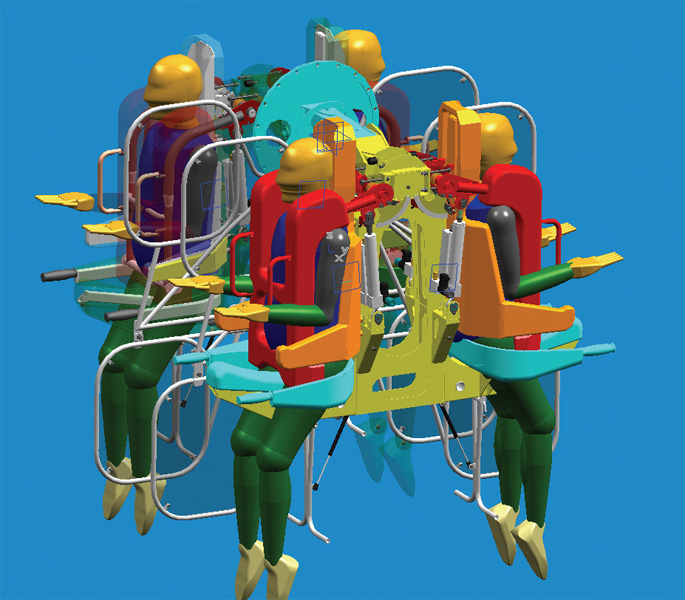

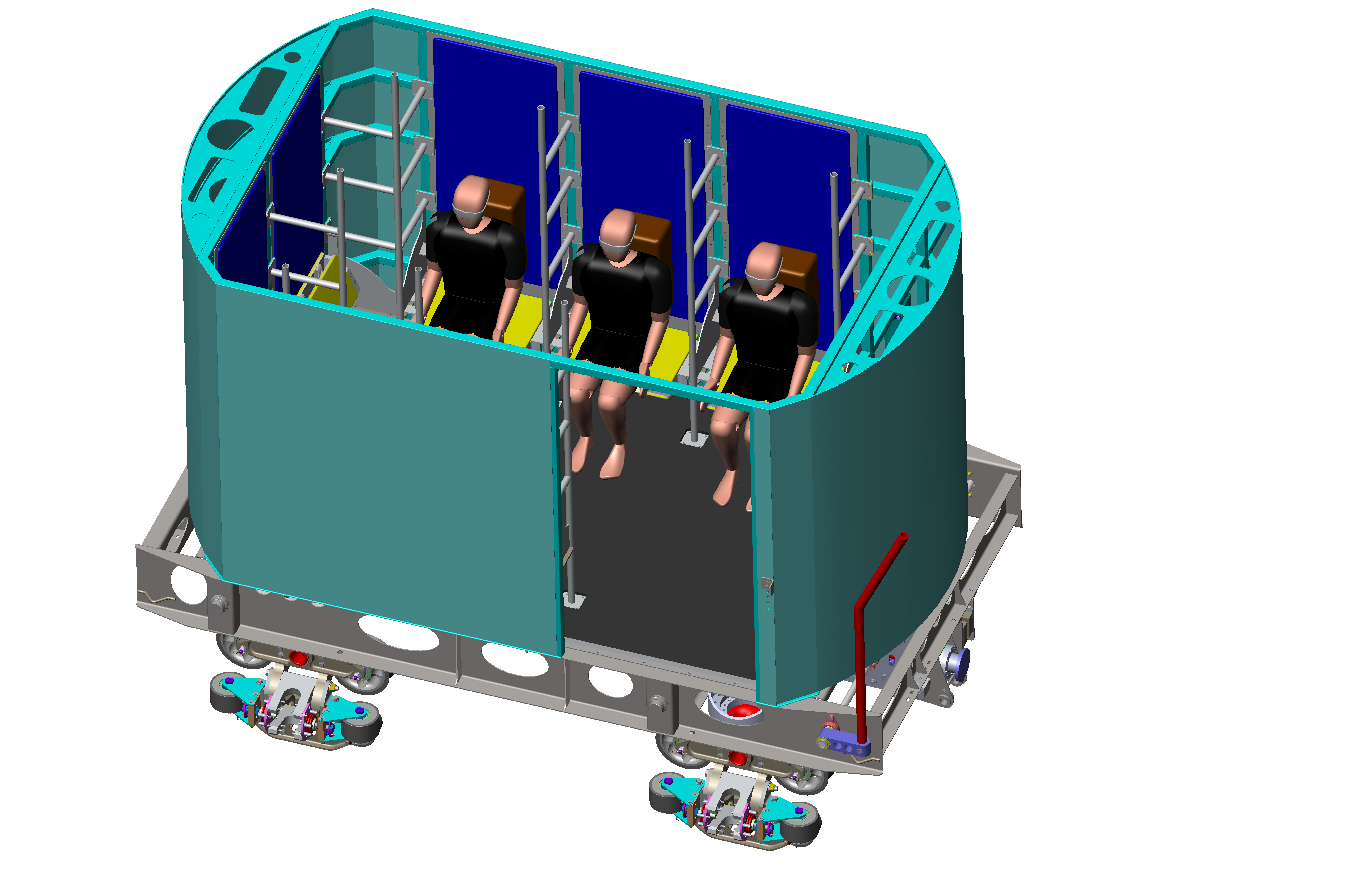

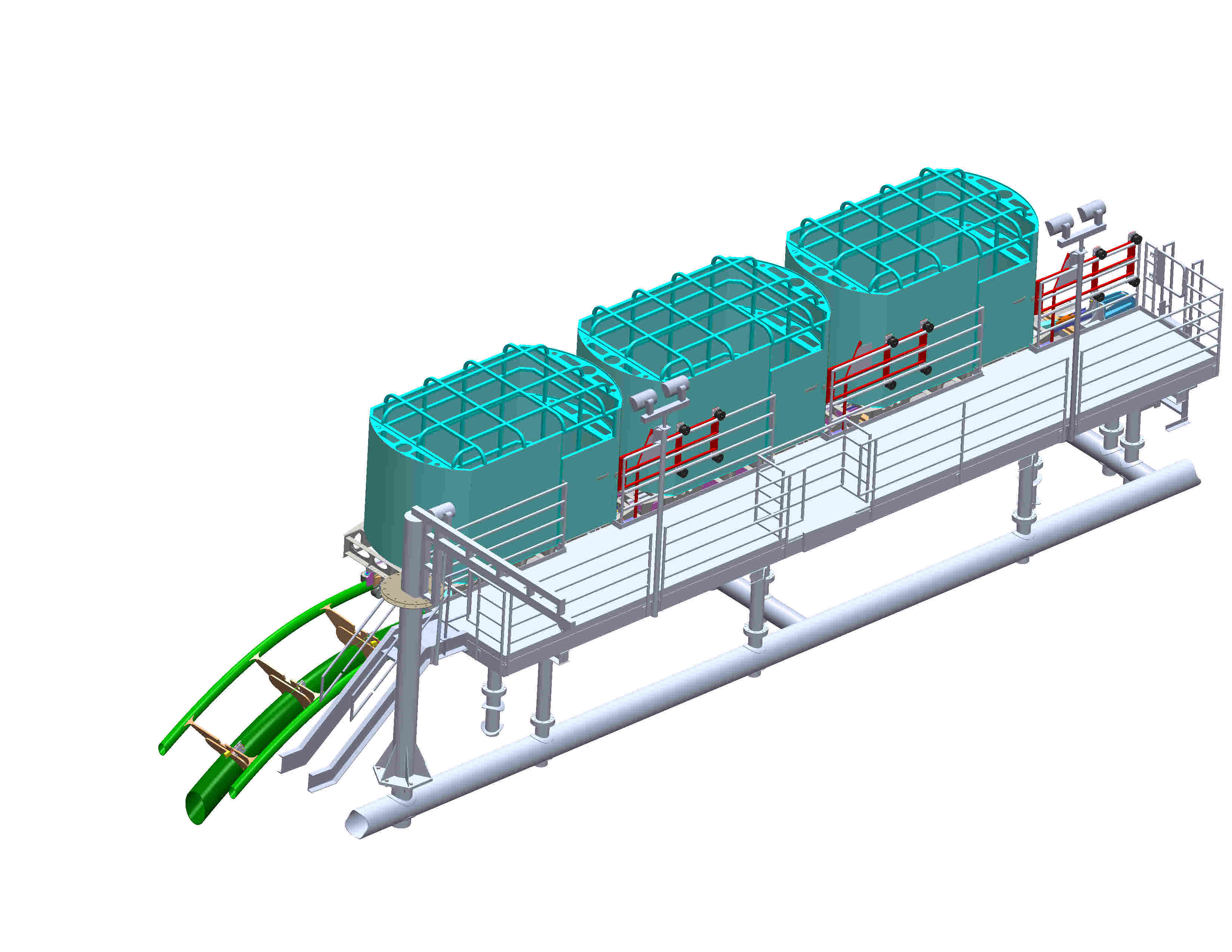

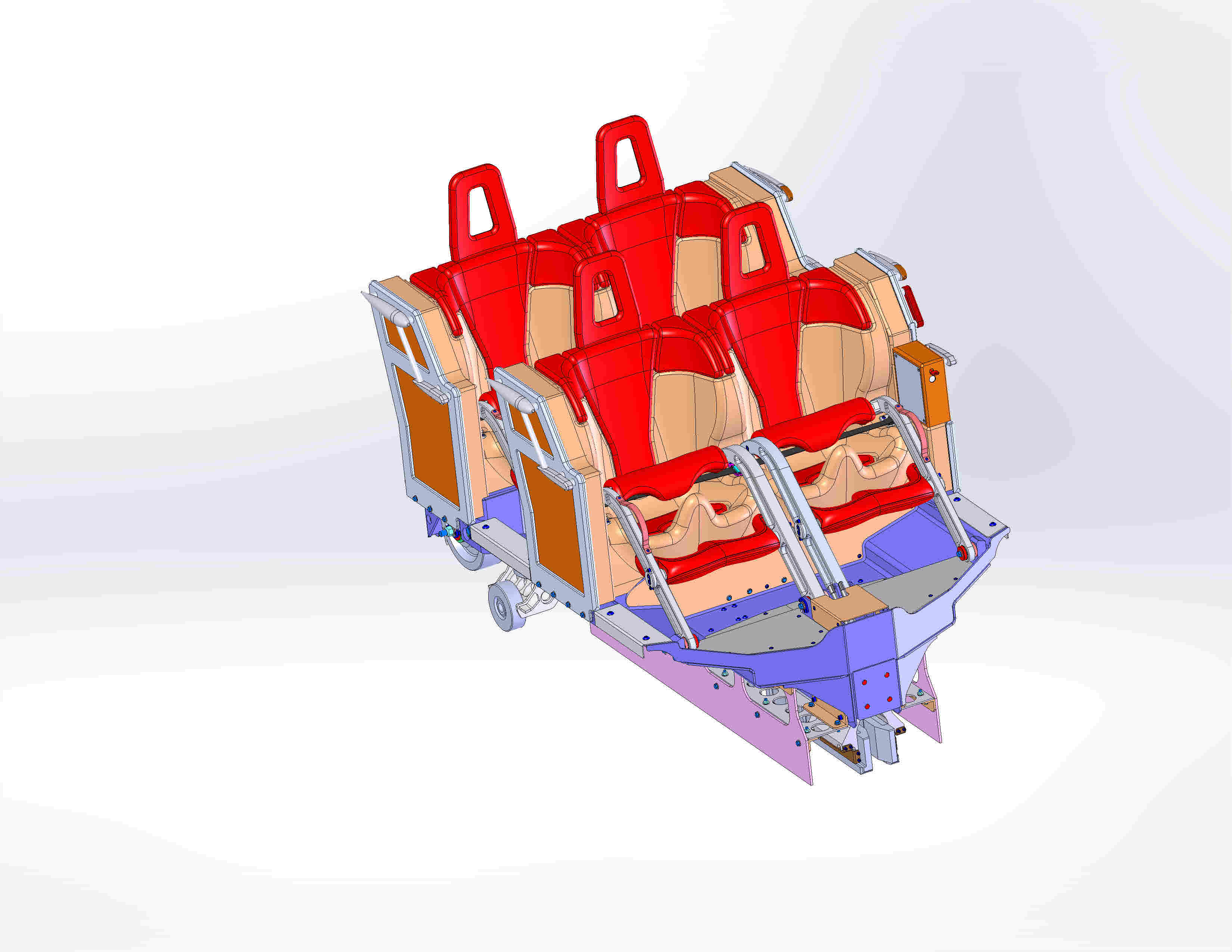

The starting point for the design of a ride is the desired motion. There are tilting rides, rotating rides, track rides and so on. The second step is ergonomics. ‘‘Considering that we transport the most precious of goods, people, an ergonomic approach is extremely important,” Fabbri explains. “We use various models of human bodies and build the ‘shell’ or seat around each of them. Then, we design accessories, such as the seat bottom or the protection bar that keeps you in place and prevents you from being ejected.”

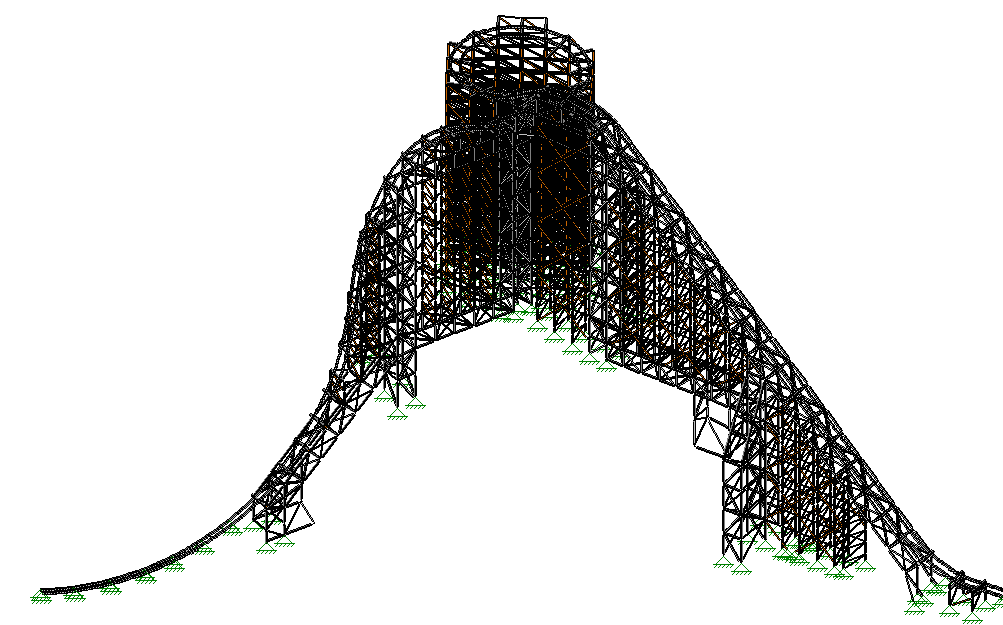

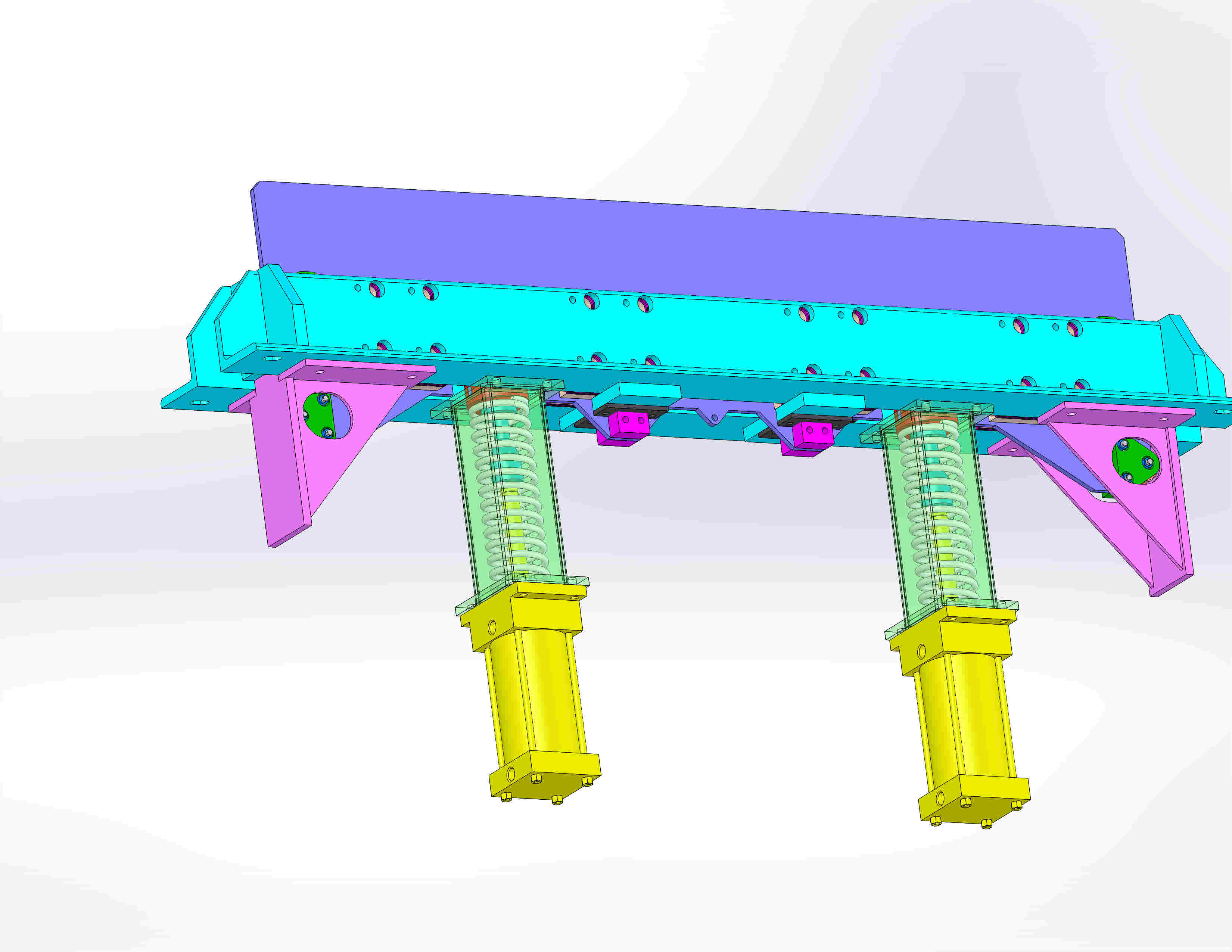

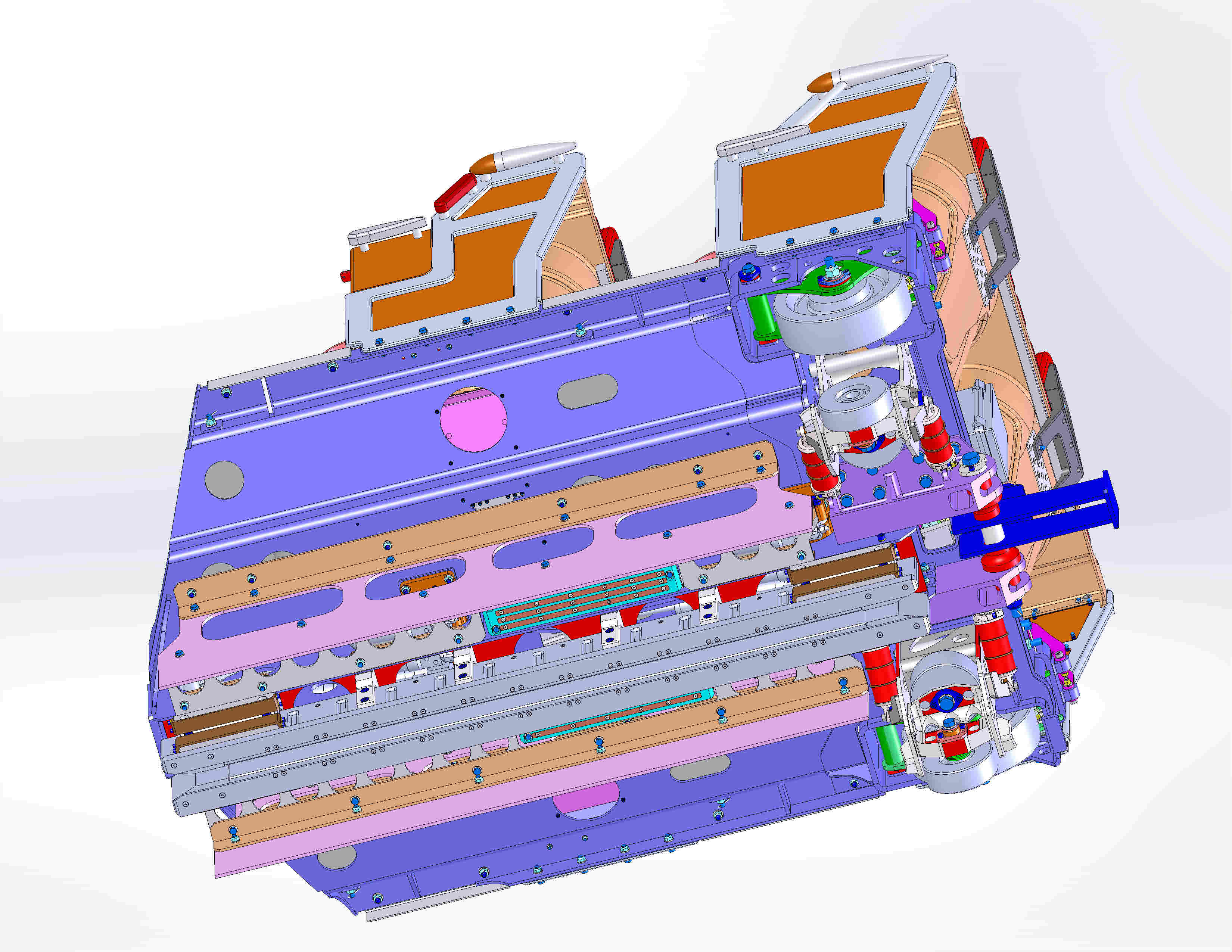

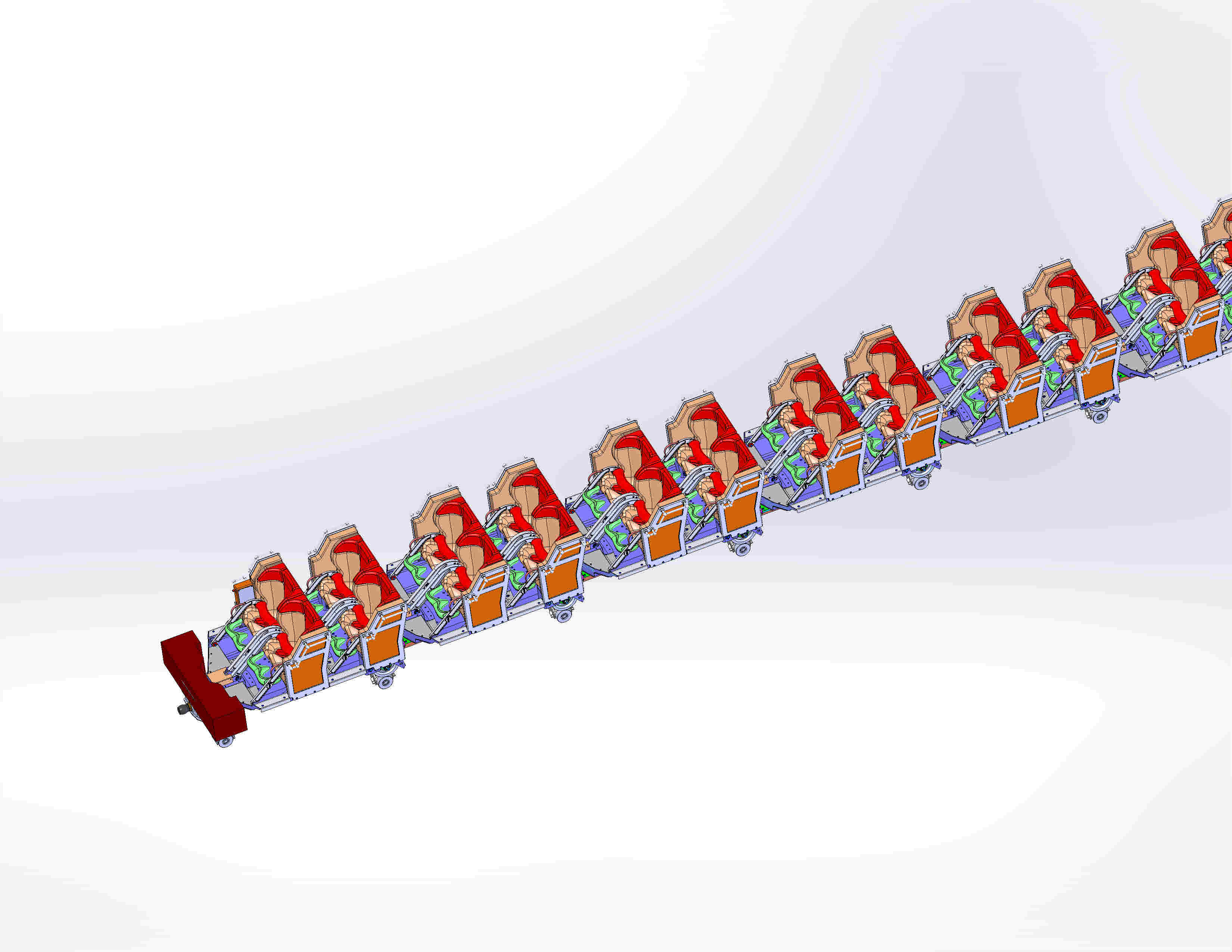

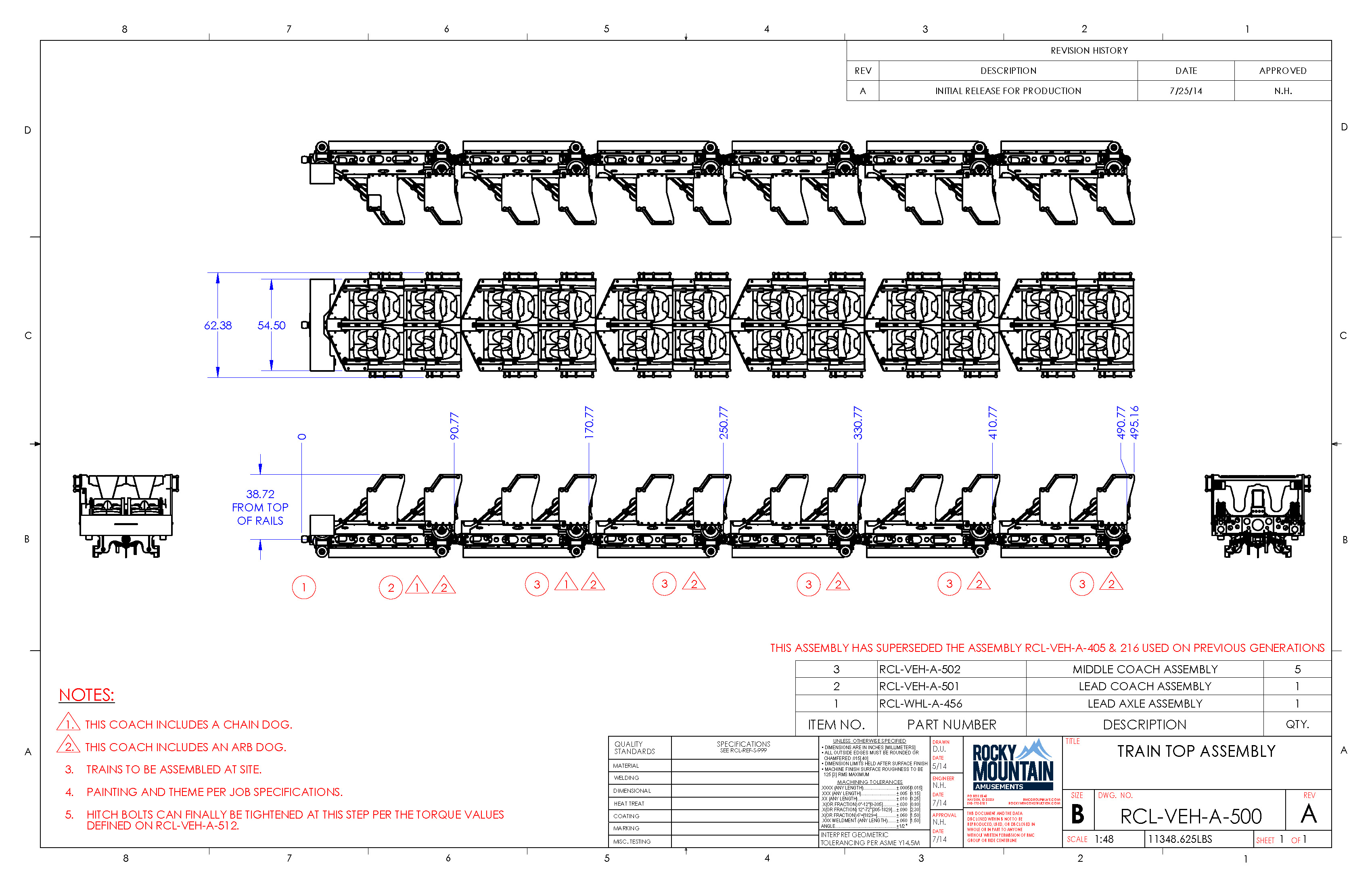

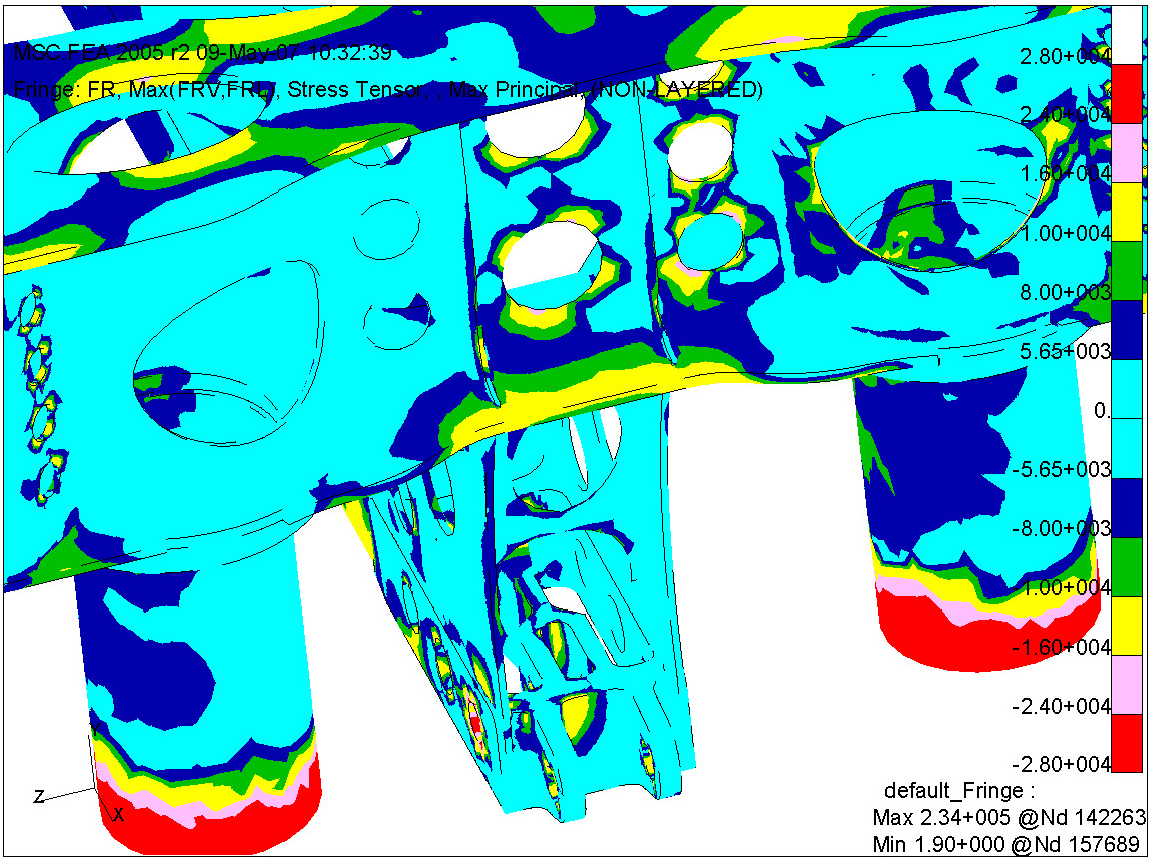

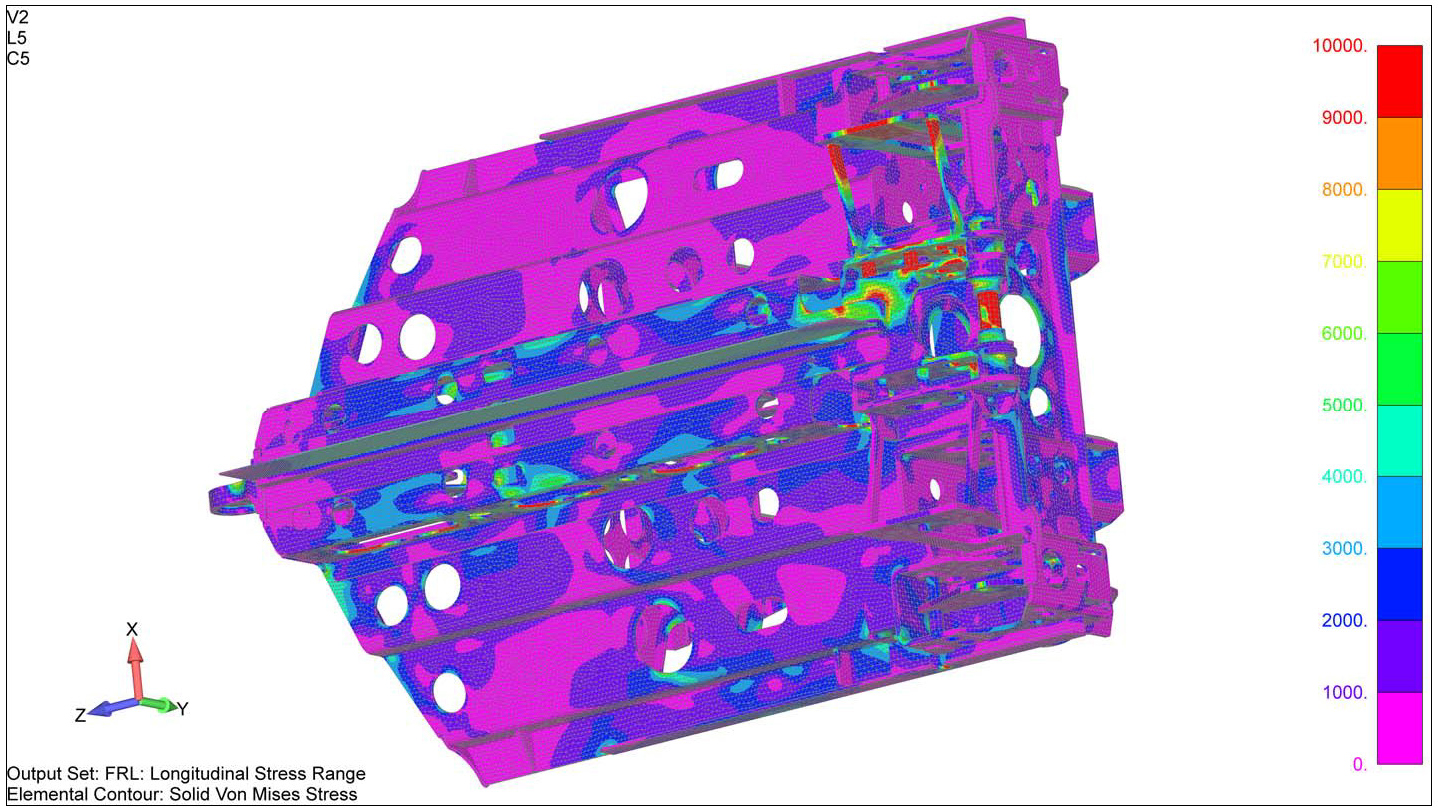

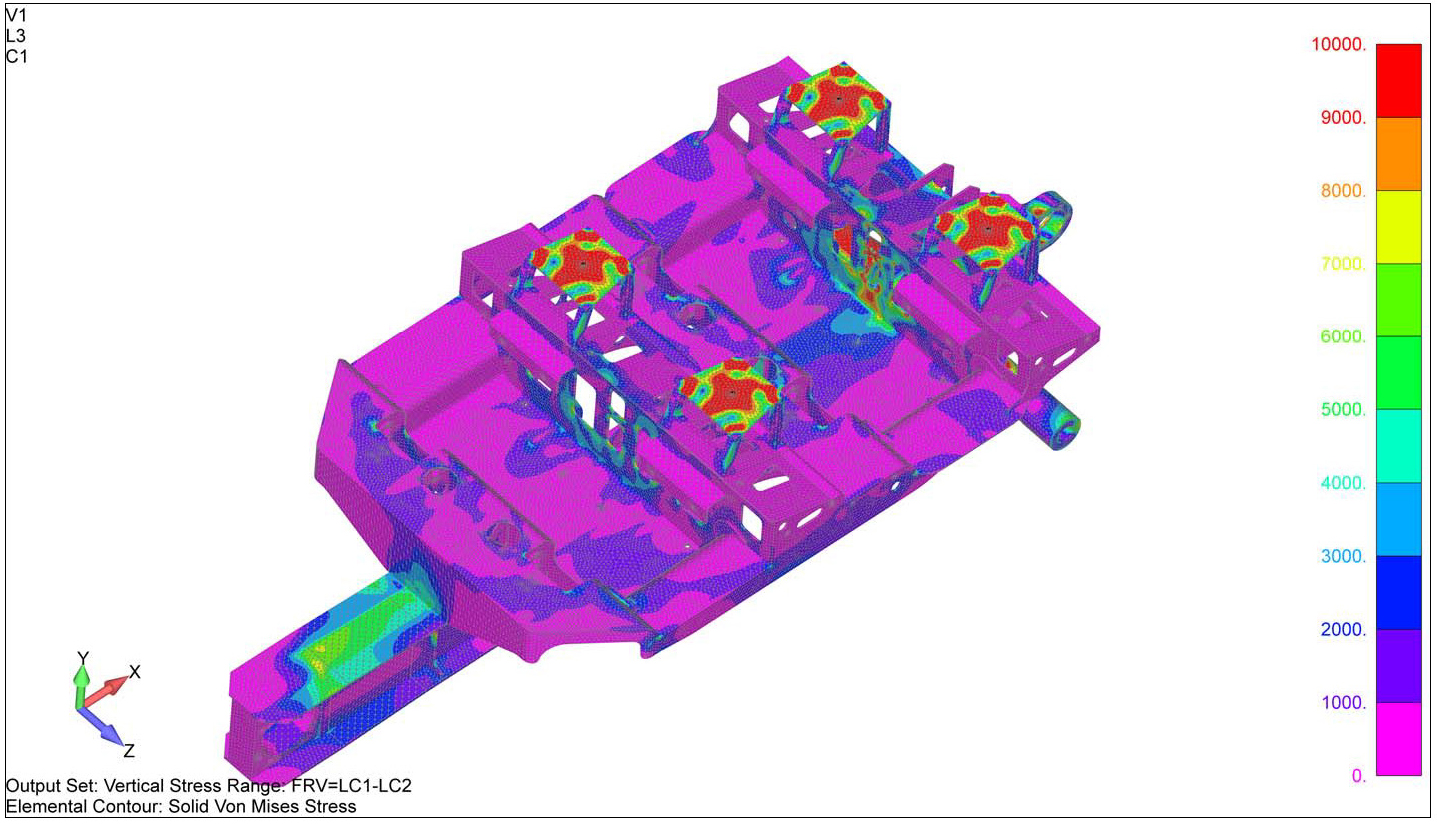

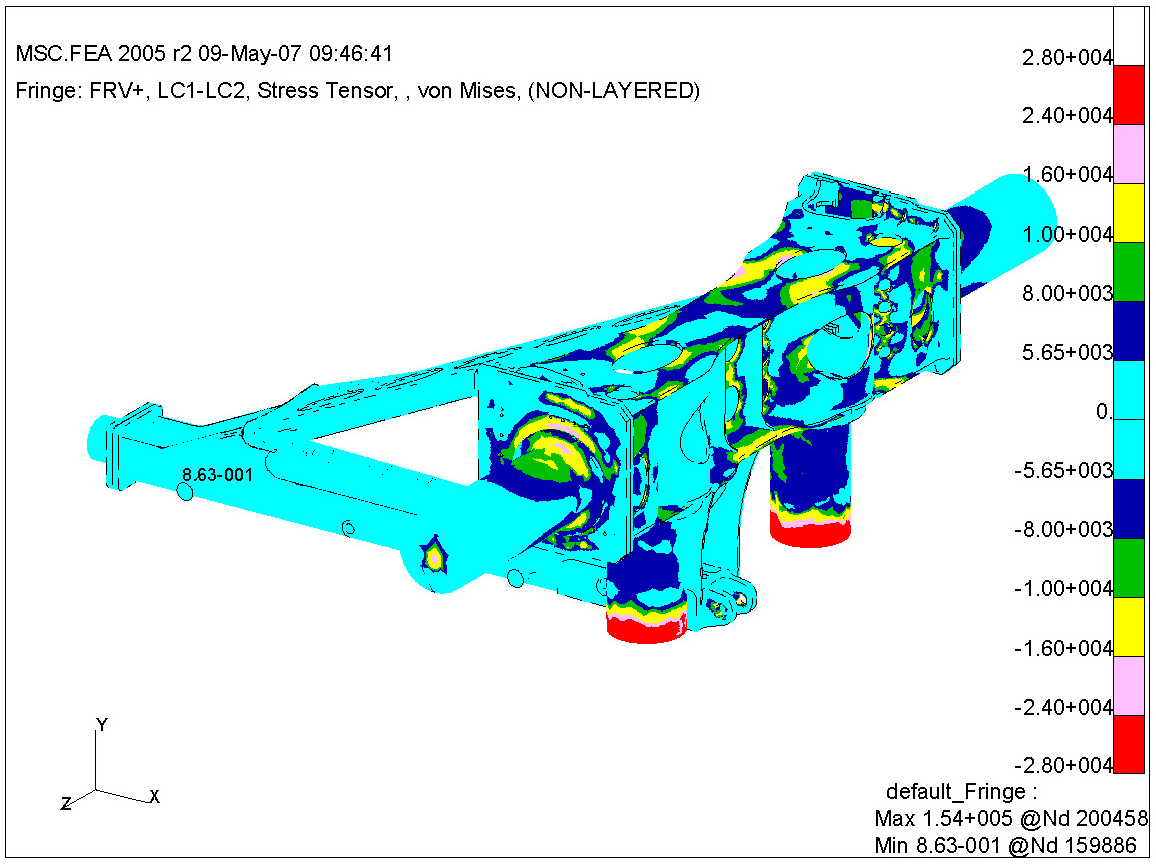

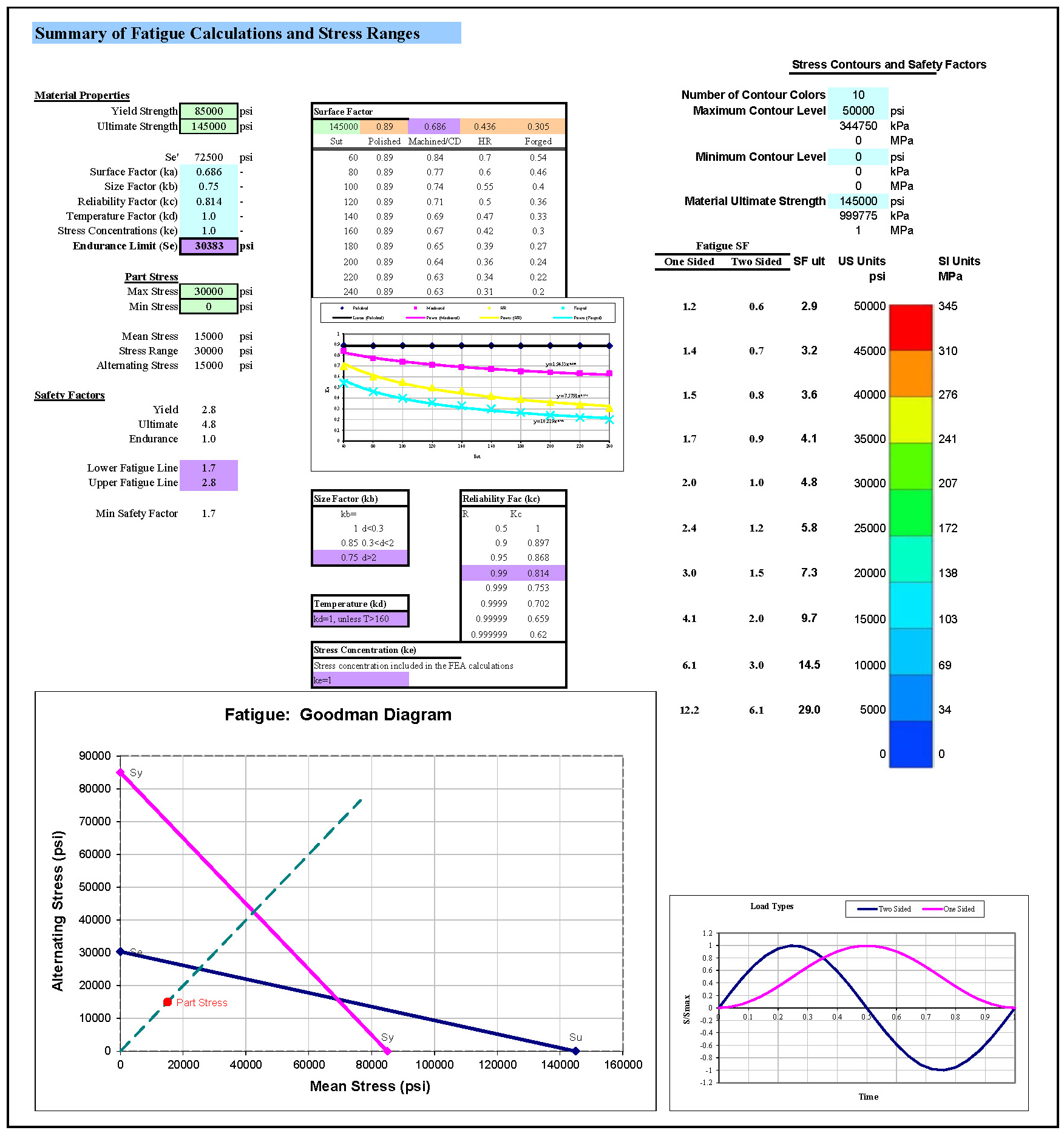

Once weights and movements have been calculated, designers start the virtual prototyping process in Solid Edge. The ability to preview designs while they are still in the early stages stimulates creativity. Virtual prototypes make it possible to create simulations and check part movements, accelerations and forces. Once these are known, the next step is finite element simulation, which allows designers to shape the metal structures based on the results of dynamic simulations. Another use of Solid Edge is for 3D simulations of assembly and disassembly. A unique characteristic of this kind of equipment is that for transport reasons, parts must be able to bend in complex ways or they must be able to be broken down into many subparts. This is actually the most difficult stage of the design. “The use of a powerful 3D CAD solution such as Solid Edge is critical, as it allows us to preview the objects and the volume of space they occupy,” Fabbri notes.

Solid Edge has not only been good for designers. The sales staff has also benefited. They can now preview colors and models of new rides without needing to create expensive prototypes. Solid Edge has also helped speed the overall development process. Now, manufacturing immediately follows design, while with the old 2D process, there was always a delay. For Fabbri Group, adding Solid Edge to its design process has made it easier and faster to deliver thrills.

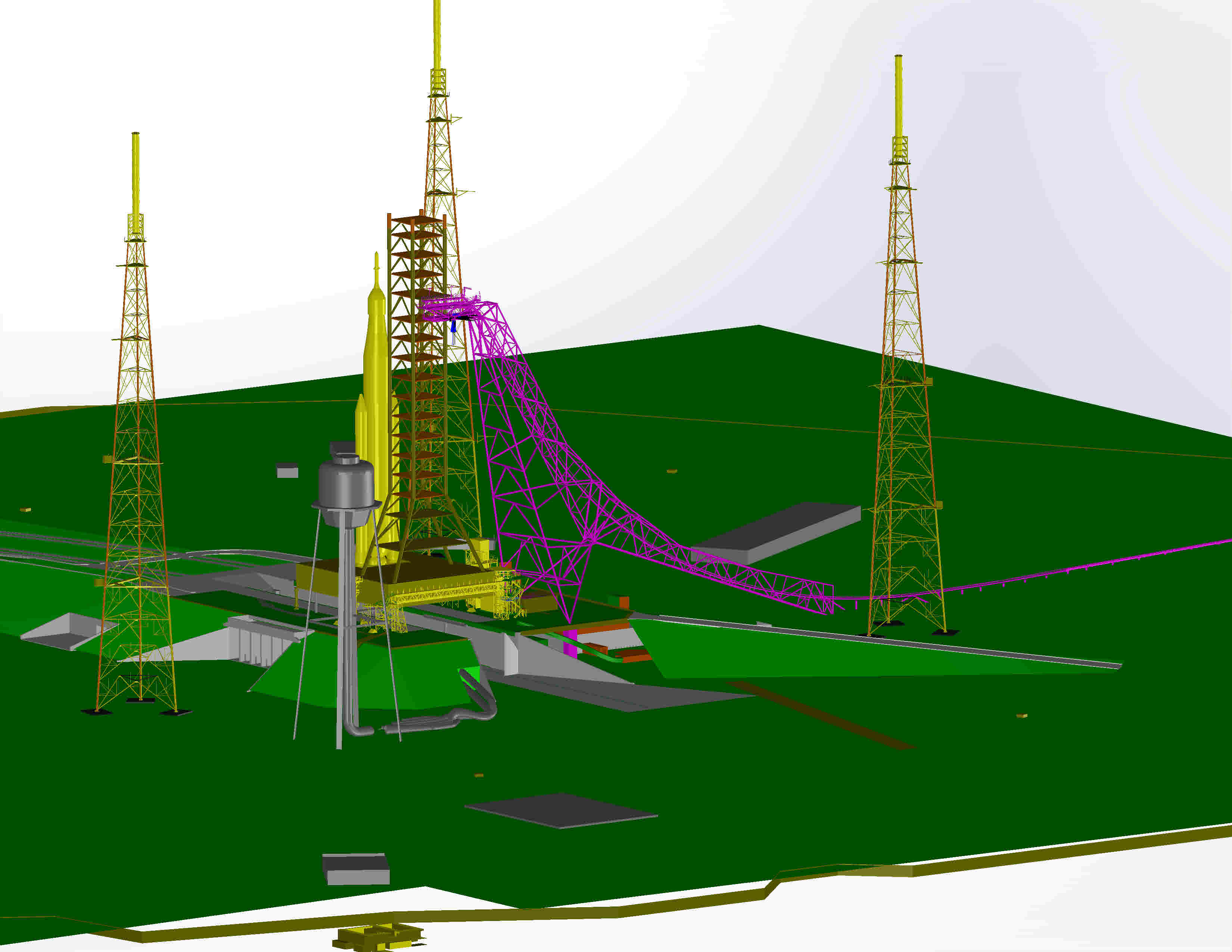

Although the design was successfully completed, the ARES I/Constellation program was cancelled prior to build.